In the world of precision manufacturing, achieving accuracy down to a fraction of a millimeter is not just a goal—it’s a necessity. From aerospace to automotive, every industry that relies on mechanical parts depends on components that fit and function perfectly. This is where CNC machining plays a critical role, enabling manufacturers to produce high-tolerance parts with remarkable precision and consistency.

What Makes CNC Machining Essential for High-Tolerance Work

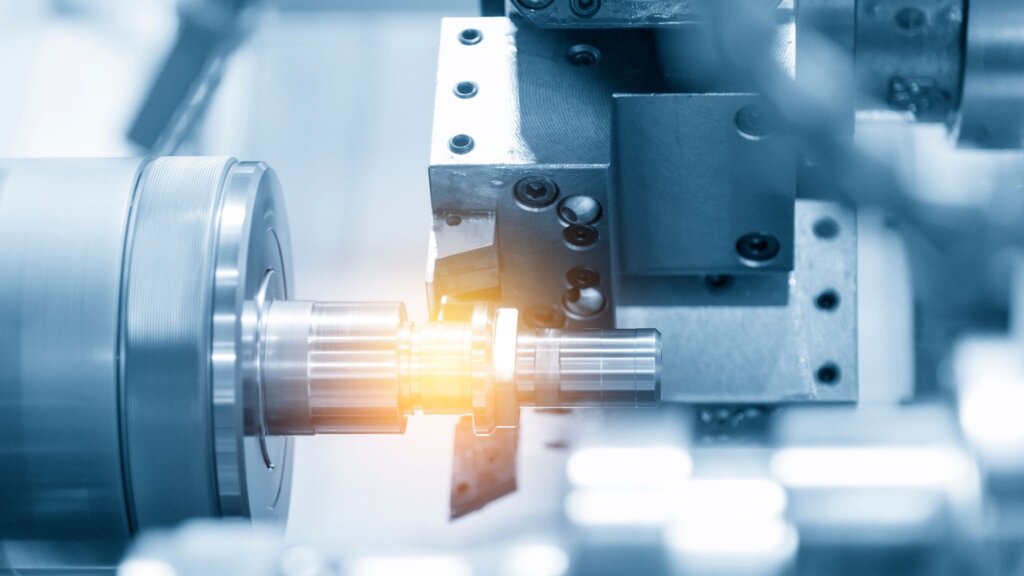

CNC (Computer Numerical Control) machining uses computer-guided tools to shape metal, plastic, or other materials with extreme accuracy. Unlike manual machining, where human skill dictates precision, CNC systems follow exact programmed instructions. This eliminates errors caused by fatigue or inconsistency, ensuring each piece meets strict specifications.

For industries that demand tight tolerances—such as medical devices, aerospace, or oil and gas—this precision is invaluable. Even a deviation of a few microns can lead to performance issues or mechanical failure. By using advanced CNC mills, lathes, and turning centers, manufacturers can maintain these microscopic tolerances with ease.

How CNC Machine Shops Achieve Unmatched Precision

Modern CNC equipment integrates advanced technologies like multi-axis movement, automated tool changers, and digital measuring systems. These features allow operators to perform complex cuts and finishes without stopping production. In regions like Texas, where industrial innovation thrives, facilities such as a cnc machine shop Houston stand out for delivering parts that meet the most demanding engineering standards.

Temperature control and calibration also play vital roles in achieving precision. High-end machine shops maintain climate-controlled environments to reduce thermal expansion in materials—a key factor when working with metals that expand or contract under heat. This meticulous control ensures that the final components remain within the required tolerance levels throughout the production process.

The Role of Skilled Machinists in CNC Precision

While CNC systems are automated, the expertise of skilled machinists remains essential. They interpret blueprints, select proper tooling, adjust feeds and speeds, and perform quality inspections. A qualified machinist understands not just how to run the machine, but how to optimize every aspect of the process for peak performance.

A cnc machine shop Dallas often combines traditional machining experience with modern CNC technology, giving clients the advantage of craftsmanship backed by innovation. This blend of human knowledge and automation helps ensure that every finished component is both functional and durable.

Why High Tolerance Matters in Industrial Components

High-tolerance machining ensures reliability, safety, and longevity in mechanical systems. When parts fit together with perfect precision, they experience less wear, maintain alignment, and reduce the risk of breakdowns. In critical sectors—like defense or energy—where downtime can be costly or dangerous, this level of quality is non-negotiable.

Moreover, precision machining supports innovation. Engineers designing new machinery or prototypes rely on accurate components to test and refine their ideas. A single flaw can derail an entire project, making CNC machining an indispensable partner in product development and manufacturing.

The Future of CNC Machining

As technology advances, CNC machining continues to evolve with higher speeds, better sensors, and smarter programming. Artificial intelligence and IoT integration are already improving predictive maintenance and workflow efficiency. The next generation of machining will likely combine data-driven insights with ultra-high-speed automation, further raising the bar for accuracy and repeatability.

In a competitive manufacturing landscape, CNC machining remains the foundation of precision engineering. Whether it’s a cnc machine shop Houston specializing in aerospace components or a cnc machine shop Dallas producing parts for energy systems, both showcase the same core principle: excellence through precision. High-tolerance machining doesn’t just create parts—it builds the backbone of industries that move the world forward.