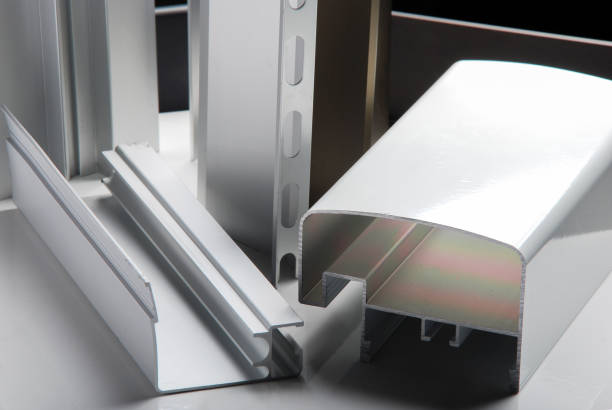

In today’s construction and manufacturing industries, efficiency and durability are key. Plastic profiles are no longer just substitutes for wood or metal; they are integral components that shape how modern projects perform. Among them, rigid PVC extrusion in India has become one of the most trusted methods for producing profiles with consistent strength, design flexibility, and long service life. It is used in window frames, cable ducts, door panels, piping, and countless industrial parts.

Yet, despite its proven advantages, businesses often face setbacks because of mistakes in the selection process. From overlooking long-term costs to underestimating compliance needs, these errors can impact both budgets and timelines. Below, we explore 11 common mistakes to avoid when choosing rigid PVC extrusion, along with practical solutions that ensure long-term success.

1. Ignoring Material Quality

Not all rigid PVC is the same. Some formulations use high-grade resins and stabilisers, while others rely on cheaper blends that compromise performance. A poor-quality profile may crack, fade, or lose strength over time.

👉 Solution: Ask for data sheets and material specifications before placing bulk orders. Ensure that the PVC grade suits your project’s requirements, whether it is construction cladding or industrial insulation.

2. Overlooking Design Flexibility

Rigid PVC extrusion is highly adaptable. Unfortunately, some buyers settle for standard profiles without realising the design freedom extrusion allows.

- Complex cross-sections can be achieved without extra machining

- Functional features like grooves, lips, and snap-fit joints can be integrated

- Surface finishes and colours can be added during production

👉 Tip: Collaborate with manufacturers early to design extrusion profiles that reduce secondary processing.

3. Failing to Match Application Needs

PVC extrusion used for a piping system will differ from that used in window frames. Each application demands unique tolerance, strength, and chemical resistance.

👉 Example: A profile meant for electrical cable protection must resist heat and provide insulation, while profiles for construction cladding must withstand UV exposure and impact.

4. Neglecting Tolerance Requirements

Small errors in dimension can cause big problems during installation. Some projects demand tight tolerances, especially where multiple parts interlock or where water and air tightness are critical.

👉 Solution: Ensure your supplier follows strict quality control processes, with tolerance levels clearly stated in the contract.

5. Overlooking Long-Term Costs

Rigid PVC is cost-effective, but buyers sometimes focus only on the initial price. In reality, extrusion offers lifecycle savings due to lower maintenance and replacement needs. Profiles resist corrosion, moisture, and weathering better than wood or metal.

👉 For a detailed breakdown, read about 5 Ways Rigid PVC Extrusion Reduces Long-Term Maintenance Costs.

6. Choosing Suppliers Without Proven Expertise

Experience in extrusion matters. New suppliers may lack the equipment or knowledge to deliver consistent results in bulk production.

👉 Checklist when evaluating suppliers:

- Years of experience in rigid PVC extrusion

- Capability for bulk supply

- Customisation services offered

- Industry certifications or audits

7. Ignoring Environmental Resistance

Rigid PVC is naturally resistant to many chemicals and weather conditions, but specific environments may need additives for better performance.

👉 Examples:

- UV stabilisers for outdoor applications

- Flame retardants for electrical applications

- Impact modifiers for heavy-duty industrial use

Failing to ask for these can shorten the product’s lifespan.

8. Underestimating Production Volume Needs

Rigid PVC extrusion is highly efficient for bulk production. However, small orders often raise costs due to frequent setup changes.

👉 Tip: Plan procurement in bulk wherever possible. Consistent volume ensures lower costs per unit and standardised quality across all parts.

9. Not Checking Compliance and Certifications

Rigid PVC profiles are often used in projects where compliance with building codes, fire safety, or environmental regulations is mandatory.

👉 Solution: Ask suppliers for ISO certifications, RoHS or REACH compliance, and documentation for any regional standards required in India or international projects.

10. Skipping Customisation Options

Rigid PVC extrusion can save both time and money by integrating features directly into the profile. However, many businesses do not explore these options and end up adding secondary processing steps later.

👉 Customisation ideas:

- Embedding company logos

- Adding anti-slip textures

- Colour-matching profiles for branding consistency

11. Ignoring Sustainability Factors

With sustainability becoming a global priority, businesses that fail to consider recyclability risk falling behind. Rigid PVC is recyclable, but not all suppliers use eco-conscious methods.

👉 Tip: Work with manufacturers who reprocess scrap and offer sustainable practices. This not only reduces environmental impact but also strengthens your reputation with eco-conscious clients.

Why Avoiding These Mistakes Matters

Rigid PVC extrusion offers strength, cost efficiency, and design versatility, but overlooking key factors can lead to poor results. Whether it is for large-scale construction, automotive fittings, or industrial machinery, choosing the right extrusion approach ensures long-lasting performance and reduced costs.

By avoiding these 11 mistakes, businesses can secure better returns, smoother installations, and profiles that truly meet functional and design expectations.

FAQs on Rigid PVC Extrusion

Q1. What is rigid PVC extrusion used for?

Rigid PVC extrusion is used to produce profiles for construction, automotive, packaging, and electrical industries. Common examples include window frames, conduits, cladding, and machine components.

Q2. Why is rigid PVC extrusion in India popular?

It is popular due to its cost efficiency, durability, and ability to support bulk production. Indian manufacturers offer large-scale supply with consistent quality.

Q3. Can rigid PVC extrusion be customised?

Yes. Profiles can be made in different shapes, colours, and finishes. Functional features like locking mechanisms or grooves can be included directly during extrusion.

Q4. How durable is rigid PVC extrusion outdoors?

With additives like UV stabilisers, rigid PVC profiles perform well against sunlight, moisture, and temperature changes, making them suitable for long-term outdoor use.

Q5. How does rigid PVC compare to wood or metal?

Rigid PVC is lightweight, corrosion-resistant, and needs little maintenance. Unlike wood, it does not rot, and unlike metal, it does not rust, making it highly reliable for bulk use.

Conclusion

Rigid PVC extrusion continues to be one of the most reliable processes in modern manufacturing. By learning from common mistakes, such as ignoring compliance, underestimating design potential, or focusing only on upfront costs, businesses can make better decisions. For industries seeking durability, versatility, and cost savings, rigid PVC extrusion remains a trusted solution that supports both immediate project goals and long-term performance.